Automate your energy audits

Leave the clipboard in the truck. Automate the data collection, the engineering math, and the report writing, so you can focus on the actual engineering.

Schedule a DemoCapture Data Without the Paperwork

Stop transcribing handwritten notes. Capture assets, nameplates, and photos on your phone, even when you're offline in a basement boiler room.

Explore KawiLens →Capture

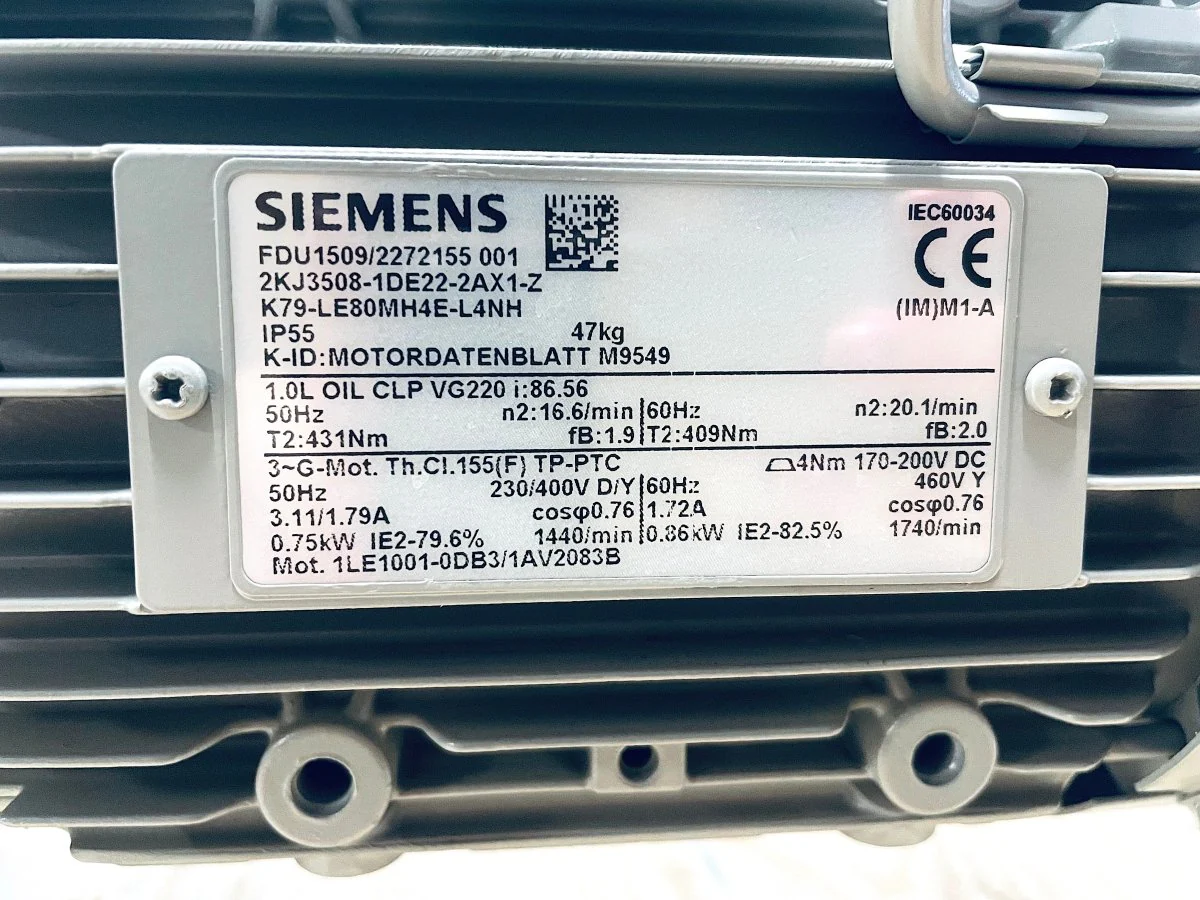

Extract voltage, amps, and model numbers from photos instantly.

Tag

Link thermal images and notes directly to the specific equipment.

Sync

Keep working in dead zones. Data syncs when you reconnect.

Smart Inventory

Log equipment fast using pre-built templates

Smart Inventory

Log equipment fast using pre-built templates

Instant OCR

Auto-extract voltage and specs from nameplate photos

Photo Tagging

Link thermal images and notes directly to the asset

Offline Mode

Keep working in basements without internet access

Team Sync

See your team's progress update in real-time

Asset Inventory

Ford Dearborn Plant - Audit #248

Boiler Room

0/12 AssetsAssembly Line A

5/18 AssetsPaint Shop

8/8 AssetsHVAC System

0/15 AssetsClean Data, Fast

Upload bills. Get normalized baselines instantly.

See Baseline in Action →Upload

Drag & drop PDFs or Excel.

Extract

Auto-extract line items.

Normalize

Get regression baselines.

File Upload

Drag & drop PDFs and Excel files.

File Upload

Ready to Process

Drop files here

PDF, Excel, or CSV

National_Grid_Jan_2024.pdf

Production_Data_2024.xlsx

Weather_Nairobi_2024.csv

File Upload

Drag & drop PDFs and Excel files.

Data Extraction

Auto-extract tariffs and line items.

Variables

Map weather and production data.

Validation

Auto-detect gaps and outliers.

Final Dataset

Export clean, engineering-ready data.

Ditch the Spreadsheets

Pick a measure. We handle the math and physics.

Explore Workbench →Calculate

Physics engines for HVAC & more.

Model

Model energy flows.

Optimize

Rank by ROI and payback.

ECM Selection

Pick from 100+ standard measures.

ECM Selection

Choose a measure

VFD on Pump 3

Motors & Pumps

LED Retrofit

Lighting

Boiler Tuning

HVAC

ECM Selection

Pick from 100+ standard measures.

Configuration

Input system specs and conditions.

Calculation

Auto-calculate savings with physics engines.

Financials

Get instant ROI, payback, and NPV.

Project List

Rank projects by savings.

Generate

AI writes the summary.

Format

Auto-embed charts & tables.

Export

Export to PDF, Word, or PPT.

Template Select

Pick ASHRAE, ISO, or custom formats.

Template Select

Pick ASHRAE, ISO, or custom formats.

AI Writing

AI writes the technical narrative.

Data Tables

Embed charts and math instantly.

Review

Collaborate with inline comments.

Download

Export to PDF, Word, or PPT.

Select Template

Choose your audit standard

Energy Survey

Detailed Analysis

Energy Management

Build Your Own

Early Access Program

We are currently onboarding a limited number of auditing firms to help shape the future of Kawibot. Get full platform access and direct support from the founding team.

Custom

We'll tailor a package that fits your firm's workflow.

KawiLens

Offline data collection app

Baseline

Intelligent bill processing

Workbench

Engineering analysis suite

Reporter

Automated report generation

White-Glove Onboarding

We'll help migrate your existing Excel templates

Priority Support

Direct access to our engineering team

Questions from the Field

We know you're skeptical. Here are the answers.

Ready to modernize your audit process?

Let's TalkThe Clipboard Era is Over

You didn't get an engineering degree to format Word documents. Join the early access program and get back to the work that matters.